A checkout counter conveyor belt is the backbone of your desired service. It is a system of pushing items on a belt and extracting them from it, with each item passing under some sort of sensor. This article will explain how this system works, with helpful links to further help you understand what is going on during the process.

What is a Checkout counter Conveyor Belt?

A checkout counter conveyor belt is a type of conveyor belt that moves items along aisles or a store. It is typically used in stores where people are checking out, such as groceries stores and pharmacies. The belt speeds up the process of checking out by grouping items together so that customers can quickly and easily pick what they want. How Does a Checkout Conveyor Belt Work?

A checkout counter conveyor belt is made up of several different types of components. The most common ones include the conveyor belt drive motor, the belts themselves, and sensors to detect items as they pass through. Every checkout counter conveyor belt system also has a control unit that tells it what to do and how fast the belt should move. Some systems have cameras or other devices to scan the items being scanned, but this is not usually necessary for most conventional checkout lines.

What Are the Parts of a Checkout Counter Conveyor Belt?. The most basic parts of a checkout conveyor belt are the driveshaft and pulley system that moves items along the belt.A detector is a device that detects the presence of an item within range and triggers an action by the controller. The controller then decides if the item is being scanned, returned to stock, or rejected. If it is accepted, the controller uses what is known as a sensor issue to determine which checkout conveyor belt system should be used. The parts above are common across most checkout conveyors.

How does a Conveyor Counter Belt work?

When you check out at a store, the checkout counter conveyor belt moves your items from the counter to a storage area. The belt has small containers that hold each item. As you put an item in a container, the belt moves it to the next container. The belt moves at a fast speed but stops when it reaches your items. The belt can hold about 50 items at once. If you want to check out more than that, you need to go to another cashier.

What are some other uses for Conveyor Belts?. A conveyor belt is also used in factories and manufacturing plants. In these places, the belt moves raw materials or finished products from one area to another. You can see the conveyor belt when you visit a factory or manufacturing plant. It carries materials or parts between areas of the factory floor.

-

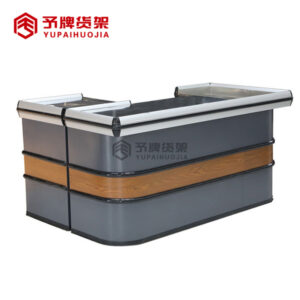

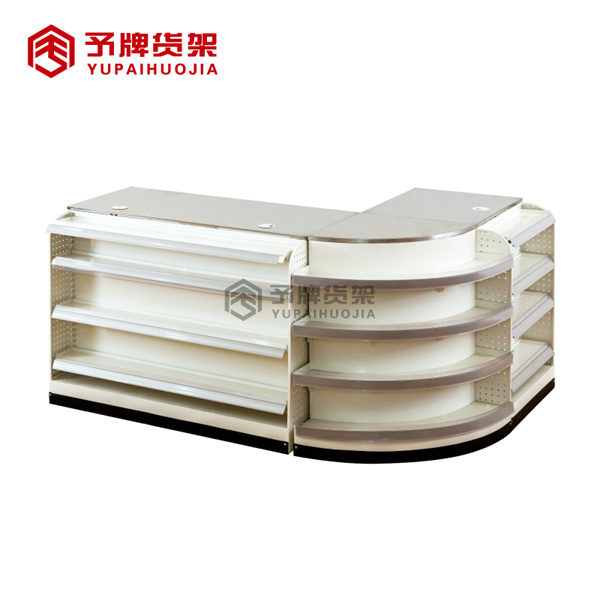

Wooden Style Supermarket Checkout Counter manufacturer & supplier

Wooden Style Supermarket Checkout Counter manufacturer & supplier -

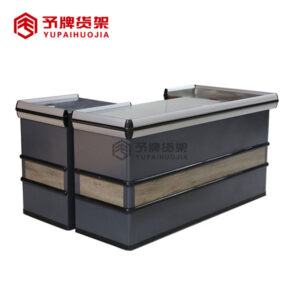

Supermarket Cashier Counter with Platform manufacturer & supplier

Supermarket Cashier Counter with Platform manufacturer & supplier -

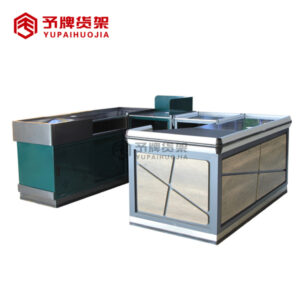

Supermarket Cash Counter with Cash Box Hole

Supermarket Cash Counter with Cash Box Hole -

Supermarket checkout counter with conveyor belt for saleRated 5.00 out of 5 based on 1 customer rating

Supermarket checkout counter with conveyor belt for saleRated 5.00 out of 5 based on 1 customer rating -

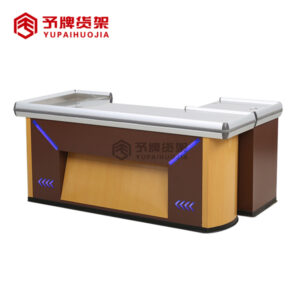

Supermarket Checkout Counter With LED Light

Supermarket Checkout Counter With LED Light -

China Supermarket retail checkout counter manufacturer

China Supermarket retail checkout counter manufacturer -

Table Desk Checkout Counter with Useful Storage Space

Table Desk Checkout Counter with Useful Storage Space -

Table Desk Supermarket Checkout Counter For Sale

Table Desk Supermarket Checkout Counter For Sale

When does it speed up or slow down?

The checkout counter conveyor belt is one of the busiest areas in any store. It’s crucial that the belt speed up and slow down at just the right time so that items can be picked up and deposited into a customer’s cart quickly and easily. Here’s how it works: when an item is put on the belt, it travels along the belt towards the point where it will be picked up by a scanner.

If the item is smaller than the width of the scanner, then it will slide through the scanner and onto a shelf above. If the item is larger than the width of the scanner, then it will stop at the bottom of the scanner and be lifted up by a sensor so that it can be placed in a bag or box.

How many different types of belts exist?

A checkout counter conveyor belt is a type of conveyor system that helps a store process large quantities of goods quickly and efficiently. The belt typically uses a series of small belts to move items along, which helps reduce the amount of time that customers have to spend at the checkout counter.

There are many different types of checkout belts, each with its own unique advantages. Some belts use a series of small, horizontal belts to move items along. This type of belt is best for products that don’t weigh much, like candy bars or cigarettes. It can take up to twice as long for an item to go through this type of belt than it would using a standard checker-case conveyor system, but it’s usually more efficient because it can move lots of items at once.

Another type of belt uses a series of larger vertical belts. This type of belt is better for products that weigh more, like clothing or food. It can move an item through the belt faster than a horizontal belt can, but it can also be more expensive to install.

Conclusion

Checkout counter conveyor belts are a common sight in modern supermarkets, and for good reason. They are an effective way of speeding up the checkout process and reducing the amount of time customers have to spend waiting in line. In this article, we will explore the principles behind checkout counter conveyor belts and learn how they work. We will also look at some of the ways you can use them to improve your business. So if you’re looking for ways to speed up your checkout process or reduce customer wait times, be sure to check out a checkout conveyor belt!