The manufacturing process of supermarket shelves is to make the shelves in the factory and transport them to the supermarket for assembly.

Introduction

The shelves are the backbone of any grocery store. They are what keep your products organized and easily accessible to customers. But have you ever wondered how these shelves are made?

The manufacturing process of supermarket shelves is actually quite fascinating. It starts with a company designing the shelving unit to meet the specific needs of the retailer. Once the design is finalized, the plans are sent to a factory where the shelves are produced.

The factory workers will first cut all of the necessary pieces out of large sheets of metal or plastic. These pieces will then be assembled into the finished shelving units using welding, riveting, or screws.

Once the shelving units are complete, they will be shipped to the retailer who ordered them and installed in their store. And that’s how shelves are made!

How supermarket shelves are designed.

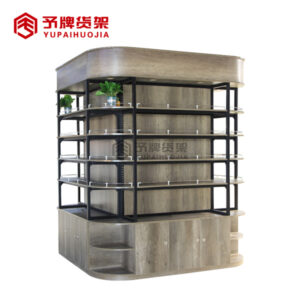

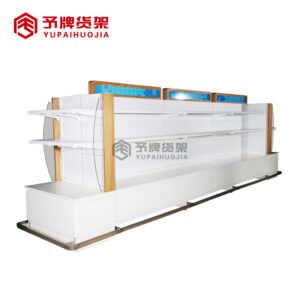

The shelves are designed to hold a variety of items and to provide easy access for shoppers. The shelves are made from a variety of materials, including wood, metal, and plastic. The shelves are usually arranged in a grid pattern, with each shelf having a specific width and depth. The supermarket shelves are also equipped with a series of hooks, which are used to hang bags or other items.

-

Steel stationery shop display rack for sale

Steel stationery shop display rack for sale -

Supermarket shelves for sale in dubai

Supermarket shelves for sale in dubai -

Pharmacy grocery display for sale

Pharmacy grocery display for sale -

Cosmetic display shelves for shop

Cosmetic display shelves for shop -

wholesale cosmetic display rack

wholesale cosmetic display rack -

Supermarket Cosmetics shelves supplier

Supermarket Cosmetics shelves supplier -

kitchenware store shelves for sale

kitchenware store shelves for sale -

Adjustable Steel Modern Shelf Steel Shelves Grocery Shelf Mini Store

Adjustable Steel Modern Shelf Steel Shelves Grocery Shelf Mini Store -

4 post retail shop racking display grocery item display rack supermarket shelf gondola

4 post retail shop racking display grocery item display rack supermarket shelf gondola

The manufacturing process of supermarket shelves.

The supermarket shelves are manufactured using a process known as roll forming. This process involves passing a sheet of metal through a series of rollers, each of which shapes the metal into the desired shape. The finished product is then cut to size and powder coated for durability.

What is the shelf life expectancy of supermarket shelves?

The average shelf life expectancy of supermarket shelves is around 10 years. However, this can vary depending on the type of material the shelves are made out of and the amount of wear and tear they experience. For example, shelves made out of metal or glass may have a shorter shelf life than those made out of wood.

Supermarket shelves are subject to a lot of wear and tear. They are constantly being loaded and unloaded with heavy boxes of merchandise, which can cause them to warp or bend over time. Additionally, the constant exposure to dust, dirt, and moisture can also cause deterioration.

Conclusion

The manufacturing process of supermarket shelves is quite simple. First, the metal frame is welded together. Next, the wire mesh is attached to the frame. Finally, the shelves are powder coated and baked in an oven to cure the finish. This process results in a strong and durable product that can withstand heavy use.